readySC™, an integral part of the SC Technical College System, is a key component of South Carolina’s economic development engine. readySC™ focuses on the recruiting and initial training needs of new and expanding organizations in South Carolina. The program leverages the system across the state to provide recruiting, assessment, training development, management and implementation services to qualifying companies.

Rubber & Miscellaneous Plastic Products

(Bridgestone, Michelin, Continental)

Transportation Equipment Manufacturing

(Boeing, Lear, GE Aviation, GKN Aerospace)

Textile Mills

(Glen Raven Custom Fabrics, Orian Rugs)

Fabricated Metal Product Manufacturing

(Schaeffler Group USA, Gonvauto, American Tactical)

Electrical Equipment, Appliance & Component Manufacturing

(E&I Engineering, Cytec Carbon Fibers)

Average Number Trained Per Project

134 Companies

Served in FY 2016-2016

PROVEN EXPERIENCE

WITH INTERNATIONAL COMPANIES

#1

South Carolina ranks first in attracting jobs through foreign investment

(IBM-Plant Location International)

Canada

China

France

Germany

Italy

Japan

United Kingdom

CU-ICAR

The Clemson University Center for International Automotive Research (CU-ICAR) is an advanced-technology research campus where university, industry and government organizations engage in synergistic collaboration. With more than $200 million in commitments, it represents the ultimate public/private partnership, directly fueling a knowledge base critical to the automotive industry.

Advanced Powertrains

Vehicular Electronics

Manufacturing & Materials

Vehicle-to-vehicle Infrastructure

Vehicle Performance

Human Factors/HMI

Systems Integration

The master’s and doctoral automotive engineering programs are among the most exceptional in the country as a result of direct engagement with industry-leading OEM’s and suppliers on curriculum development and research capabilities and definition of industry needs.

These rigorous programs, designed with input from world-class companies such as BMW and Michelin, require foreign language training in addition to a lengthy course of study and a six-month international assignment within the industry.

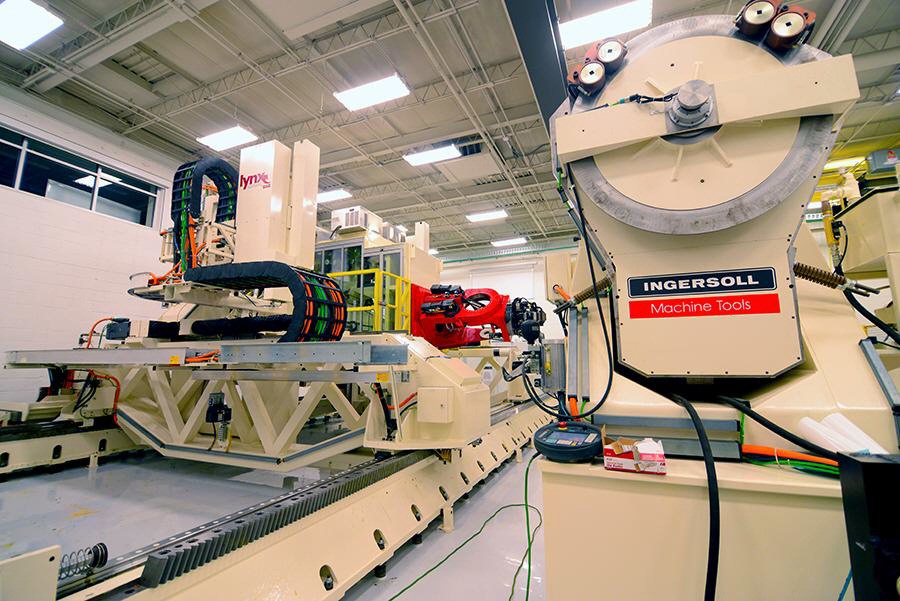

McNAIR Center

The McNAIR Center is a university center focused on aerospace-related education, research, K-12 STEM support, workforce development, and industry engagement. The McNAIR Center research team includes over 30 faculty from mechanical, chemical, civil and electrical engineering.

Facilities

- Fiber placement facility (Ingersoll Machine Tools Lynx AFP 16 x 0.250”) operational and available for large scale specimen production, prototyping and research

- Fusion bonding laboratory operational and available for induction welding, VARTM, friction stir welding and basic research

- Computational design facility operational including CAD and CAE environment, and also optimization infrastructure

Research

- Open and proprietary research support to consortia and companies

- Manufacturing research (process development, part production, assembly, qualification, DFM)

- Materials research (synthesis, surface treatments)

- Maintenance research (condition based maintenance, inspection technology, evaluation strategies, repair technology)

Product Development/Prototyping or Systems Testing/Evaluation

- Material testing and characterization (NDI, NDE, Destructive testing)

- Health monitoring (System design, testing, basic research)

- Dynamic testing

- Certification support

- Computational design, analysis and optimization